APPLICATIONS:

- Product dehydration, i.e. converting liquids like milk, drugs, and chemicals, into powders

- Drying waste streams

- Atomizing liquids

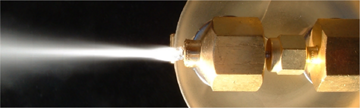

Top view of the Berkeley Lab atomizing spray nozzle

ADVANTAGES:

- Eliminates clogging

- Combines atomizing and spray drying functions

- Can be made from standard tube fittings

- Easily serviced

- Energy efficient

- Provides high quality atomization

- Dries spray without altering the spray pattern

Head-on view of the atomizing nozzle.

ABSTRACT:

Duo Wang and Mark Modera have designed an atomizing nozzle that eliminates clogging. The Berkeley Lab nozzle uses the high velocity gas efflux to create a layer of ambient temperature air around the tube containing the liquid to be atomized. This feature minimizes heat transfer from the gas to the liquid, thus eliminating premature drying. Several other design features also help to eliminate clogs.

The Berkeley Lab nozzle can be fed with heated gas for spray drying or unheated gas for just atomization and can be constructed from standard tube fittings. Hand-tightened installation of the liquid tube makes servicing easy. In addition, the design has been shown to reduce energy use by 80 percent for some applications.

For more information on this technology see: http://epb1.lbl.gov/aerosol/Atomizer.html

STATUS:

- Issued Patent # 7,156,320. Available for licensing in fields of use other than sealing HVAC systems

REFERENCE NUMBER: IB-1778 SEE THESE OTHER BERKELEY LAB TECHNOLOGIES IN THIS FIELD: