The five new technologies described below, developed by Lutgard DeJonghe, Steven Visco, Craig Jacobson and their team from Berkeley Lab’s Materials Sciences Division, add to Berkeley Lab’s existing robust patent portfolio in solid oxide fuel cells. These new inventions offer significant advances towards lowering operating temperatures and enabling rapid thermal cycling of solid oxide fuel cells. Rapid thermal cycling enables fuel cells to be turned on and off quickly, a necessity for mobile applications. All of the inventions have patents pending and are available for licensing or collaborative research opportunities.

Braze for Robust Seals with Ceramic (IB-2066)

Durable Joining of Dissimilar Materials (IB-2065)

Robust, Multifunctional Joint for Large Scale Power Production Stacks (IB-2064)

Other Berkeley Lab Solid Oxide Fuel Cell Technologies

Braze for Robust Seals with Ceramic

IB-2066

APPLICATIONS:

- High temperature seals for electrochemical devices, oxygen generators, and metal/ ceramic interfaces

ADVANTAGES:

- Enables rapid thermal cycling

- Overcomes brazing limitations without cost increases

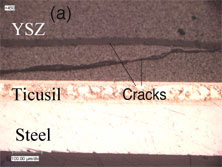

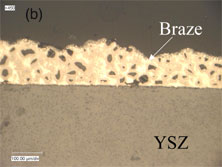

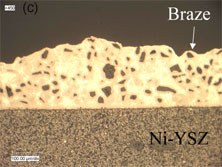

a) Existing technology cracks ceramic.

b, c) Berkeley Lab braze/ceramic interface survives 700°C rapid thermal cycling.

ABSTRACT:

Berkeley Lab scientists have developed a composite braze material that can be used to manufacture strong, gas-tight joints where one of the joining members is ceramic – typically yttrium stabilized zirconium (YSZ). The braze composition can be controlled to reduce the stress due to mismatched thermal expansion between the ceramic and the braze. Joints made using the new braze were failure-free after rapid thermal cycling up to 700°C.

Ceramics typically have a thermal expansion coefficient lower than most braze metals or alloys, which can result in weakening or cracking in the braze or ceramic. Berkeley Lab scientists add particles with low or negative expansion coefficients to the braze to attain sufficient matching to prevent this. A component that reacts with the ceramic surface can also be added, eliminating the need to metallize the ceramic prior to brazing.

Ceramic adhesives, glass, brazes, and mica have all been used as sealants in electrochemical devices, but all have limitations that prevent commercialization. This invention eliminates these barriers without increasing costs.

STATUS:

- Issued Patent ZL200580041105.0 available at www.wipo.int. Available for licensing or collaborative research.

REFERENCE NUMBER: IB-2066

Durable Joining of Dissimilar Materials

IB-2065

APPLICATIONS:

- Metal/ceramic joints in SOFCs

- Thermal barrier coatings

- Metal/ceramic bonding

ADVANTAGES:

- Survives rapid thermal cycling

- Thinner than graded joint

- Eliminates the need to introduce a third material into the joint

- High strength over a wide range of joint porosities

- Unlike graded joints, preserves contrast in material properties at the interface

ABSTRACT:

One barrier to solid oxide fuel cell manufacturing is forming robust joints between materials that don’t chemically bond with each other and/or differ greatly in form or particle size, such as metals and ceramics. Berkeley Lab scientists solve this problem by decorating the surface of the more ductile material with particles of the less ductile material via milling and then sinter-bonding this composite to the less ductile materials and/or another material that will sinter with either of the first two materials.

This technique is especially useful in devices where the utility of the joint is derived from a sharp interface between the two materials or where a third bonding material might be incompatible with system requirements. Joints made using this method have proven more durable during rapid thermal cycling than bonds relying on mechanical interlocking of articles or fibers and are more compact than graded joints.

STATUS:

- Published Patent Application. Available for licensing or collaborative research.

REFERENCE NUMBERS: IB-2065

Robust, Multifunctional Joint for Large Scale Power Production Stacks

IB-2064

APPLICATIONS:

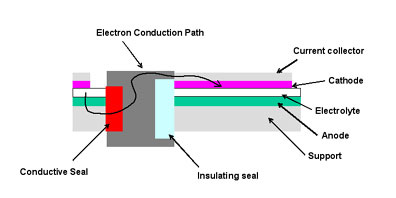

DIAGRAM OF BERKELEY LAB’S MULTIFUNCTIONAL JOINT

Sealing/joining for:

- electrochemical devices, especially metal supported tubular SOFC cells

- electronic devices operating at elevated temperatures

ADVANTAGES:

- Robust, gas-tight, and compact

- Provides electrical management over a wide range of temperature

- Promises to be inexpensive and easy to manufacture

- Enables rapid thermal cycling and endures thermal shock

ABSTRACT:

Berkeley Lab scientists have developed a multifunctional joint for metal supported, tubular SOFCs that divides various joint functions so that materials and methods optimizing each function can be chosen without sacrificing space. The functions of the joint include joining neighboring fuel cells in series, sealing cells so that distinct atmospheres don’t interact, providing electrical connections between neighboring cells, and insulating electrodes in the same cell.

The design takes advantage of highly conductive metal cell supports and edge current collection to ensure efficient power production. Traditionally, the various functions performed by the Berkeley Lab joint require physical separation, which complicates the manufacturing process and produces a less robust cell. The new joint demonstrates excellent structural integrity and is expected to be inexpensive and easy to manufacture. Novel Berkeley Lab brazing techniques make the innovative design possible. (See “Braze for Robust Seals with Ceramic”, IB-2066, above.)

STATUS:

- Published Patent Application. Available for licensing or collaborative research.

REFERENCE NUMBERS: IB-2064

SEE THESE OTHER BERKELEY LAB SOLID OXIDE FUEL CELL TECHNOLOGIES: