|

|

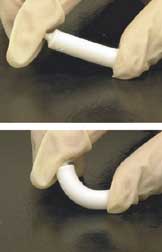

| Berkeley Lab’s flexible hydrogel-HA composite, FlexBone, has a mineral-to-organic matrix ratio approximating that of human bone. The material can be bent, compressed, and further processed to create products with a wide range of mechanical properties. | |

APPLICATIONS OF TECHNOLOGY:

- Bone implants

- Dental implants

- Bio-cements

- Flexible composites with magnetic and

electrical properties

ADVANTAGES:

- Inexpensive, rapid, and efficient

- Easily adapted to incorporate a wide range of materials

- Easily molded under ambient conditions

- Allows incorporation of 10 – 90% mineral content into hydrogels

- Enables fine-tuning of composite properties

ABSTRACT:

Carolyn Bertozzi and colleagues at Berkeley Lab have developed a rapid and inexpensive method to incorporate high mineral content into a polymer scaffold to create lightweight composite materials with a wide range of applications. The technique can be used to incorporate ceramics, metals, or semiconductors into hydrogels. These FlexBone composites will be useful in a variety of biological and non-biological applications that require a flexible polymer as well as the ability to tune strength and electronic, magnetic, conducting, and insulating properties.

The Berkeley Lab technique can be used to prepare composites of various sizes and shapes in under ten minutes, without the need for advanced equipment. The process involves mixing the polymer building blocks, the filling, and the initiators, in the desired ratio, transferring the mixture to a mold, and allowing it to solidify at room temperature. The properties of the material can easily be fine-tuned by varying parameters such as the nature of the hydrogel, the additives, solvents, and processing conditions.

In an application of the Berkeley Lab technique, Bertozzi and her colleagues prepared an artificial bone-like material by incorporating 37 – 70% hydroxyapatite mineral into pHEMA (polymer hydrogel). The hydrogel-mineral composite has sustained compressive strains up to 90% and over 600 Mpa stress without fracturing. In addition, the Berkeley Lab composite exhibits excellent mineral-gel integration. The material retains enough elasticity to be cut easily into suitable shapes and tight-fitted as a bone implant without the need for further fixation procedures. The Berkeley Lab invention will be of significant value for clinical applications involving repair of bone and dental defects as well as a wide range of non-biological applications.

STATUS:

- Issued U. S. Patent #8,552,100. Available for licensing or collaborative research.

REFERENCE NUMBER: IB-2104

SEE THESE OTHER BERKELEY LAB TECHNOLOGIES IN THIS FIELD: