APPLICATIONS OF TECHNOLOGY:

- Combinatorial DNA construction and functional screening in the following industries:

- Pharmaceuticals, especially protein-based drugs

- Agriculture

- Biofuels

- Bio-based chemicals

- Biotechnology

- Enzymes

- DNA synthesis

- Life-science instrumentation and microfluidic device industries

ADVANTAGES:

Cost and time savings compared to state-of-the-art technology:

- Uses 100–1000X smaller quantities of reagents (e.g., DNA pieces, competent cells, functional screening substrates)

- 10X faster reactions and assays; accelerated screening of DNA combinations that lead to desirable properties (phenotypes) with no plating or colony picking

- 10–100X higher number of reactions than high-density microwell plates (with 1536 wells)

- No need for polymerase chain reaction or sequencing to ascertain the genotypes of desirable candidates

- No need for expensive robotics equipment that require specially trained personnel and have large footprints

ABSTRACT:

Scientists at the Joint BioEnergy Institute (JBEI) are developing a device that can be used to efficiently assemble DNA parts, such as genes encoding enzymes, into multiple combinations, and then screen the resulting combinatorial library to identify combinations with the most desirable properties. The device combines into one microfluidic chip all of the steps necessary for this process: assembly of DNA parts; transformation and expression of these assemblies in whole-cells or cell-free platforms; cell culture; and functional assays using techniques such as colorimetric reporters, cell labeling/sorting, fluorescence imaging, and/or spectroscopy. The JBEI invention could be used in any research aimed at understanding or engineering biological processes, such as mass producing effective medications, manufacturing specialty chemicals, engineering plants and enzymes for better biofuel production, or developing crops that are more resistant to pathogens or drought.

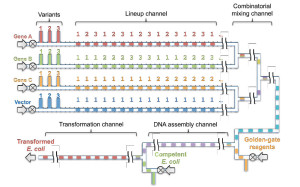

The device places each component in the process—DNA parts, reagents, cells, assayable markers—into discrete droplets that flow through microfluidic channels on a chip. Specific droplets are fused at designated times and locations in the channels to precisely control every reaction and incubation step (see Figure). Throughout the process, each combination of biological parts is kept spatially separated from the other combinations. Thus, each droplet comes off the chip with its function assessed and its combination of parts known. In addition, droplets can be removed from the chip at different points throughout the process to obtain various intermediate products such as recombinant DNA, transformed cells, labeled cells, or protein cocktails.

Figure. A schematic of a part of the microfluidic device. Different variants (1, 2, 3) of four DNA fragments (genes A-C and a vector backbone) are fed into the microfluidic chip (top left). With control valves, droplets containing each variant of each gene are generated along the ‘Lineup channel(s).’ The droplets flow from left to right and merge into the desired combinations in the ‘Combinatorial mixing channel(s)’ (top right). These combinations of parts are mixed with Golden-gate reagents (or other reagents for fusing them into recombinant DNA) (lower right); incubated in the ‘DNA assembly channel(s)’; mixed with competent cells (e.g., E. coli); and transformed into the competent cells in the ‘Transformation channel(s)’ (lower left). Not shown are the downstream sections of the device for cellular outgrowth and functional activity screening. Click on image to enlarge.

Knowing the combination of DNA present in each droplet eliminates the need for the many time-consuming and expensive steps currently used to isolate and identify the DNA sequences of the best candidates from a pooled-mixture of multiple combinations (a “single-pot combinatorial library”) following a functional selection or screening process. With existing methods, this process requires plating cells under selective pressure, picking candidate colonies, extracting DNA, and running polymerase chain reactions and/or submitting samples for DNA sequencing. Moreover, many of these steps require large personnel costs and sizeable capital investments in robotics equipment. The JBEI invention would provide labor savings by simplifying and accelerating the process and forgo the need for robotics. It would also reduce costs by using much smaller volumes (e.g., nanoliters rather than milliliters) of reagent materials.

Generating and screening multiple combinations of genes, enzymes, and other biological parts has become vital to biotechnology research and development. The state-of-the-art methods for this process are extremely expensive, do not scale well, and are often cost-prohibitive for small laboratories. The heavy molecular biology task burden also causes researchers to spend much of their time on obtaining DNA parts combinations, rather than on designing and conducting the functional activity experiments for which the researchers have a comparative advantage. The JBEI device will execute this work with greater speed and efficiency at a lower cost.

The Joint BioEnergy Institute (JBEI, www.jbei.org) is a scientific partnership led by the Lawrence Berkeley National Laboratory and including the Sandia National Laboratories, the University of California campuses of Berkeley and Davis, the Carnegie Institution for Science and the Lawrence Livermore National Laboratory. JBEI’s primary scientific mission is to advance the development of the next generation of biofuels.

DEVELOPMENT STAGE: Multiple parts of multistep process demonstrated successfully.

STATUS: Published US Patent Application US20120258487 available at uspto.gov. Available for licensing or collaborative research.

SEE THESE OTHER BERKELEY LAB TECHNOLOGIES IN THIS FIELD:

j5: Automated DNA Assembly Design Software, ECRB-2836

REFERENCE NUMBER: EJIB-2934