2011 Winner

APPLICATIONS OF TECHNOLOGY:

- Windshields and windows

- Solar panels

- Lenses for cameras, endoscopes, laparoscopes, and other optical devices

- Eyewear – goggles and glasses

- Dental mirrors

ADVANTAGES:

- Stable over time

- Inexpensive

- Does not require UV-light activation

- Excellent optical properties (high transmittance; low reflectance and refractive index)

- Self cleaning

ABSTRACT:

Samuel Mao and a team of scientists at Berkeley Lab have created superhydrophilic nanostructures that can be used as a stable antifogging agent when applied to glass. The Berkeley Lab invention does not require UV irradiation and is nontoxic.

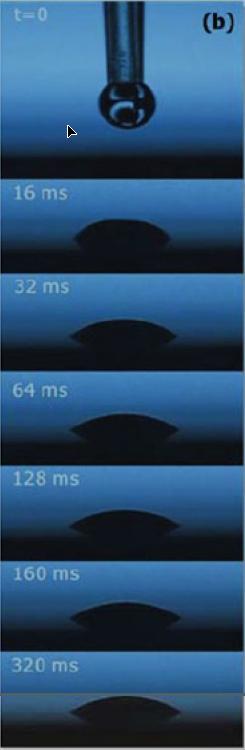

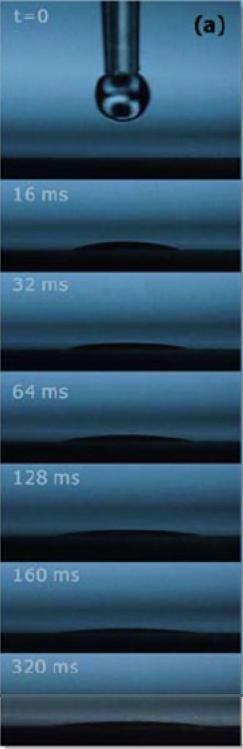

In tests, the technology continued to function efficiently after more than 20 successive wetting-dewetting cycles. The optical properties of the coating are superior to those of other formulations in demonstrating higher transmittance (> 90%) and reduced reflectance (6-8% over wavelengths of 300-2,500 nm). Tests for hydrophilicity demonstrated that water droplets spread within a couple of hundred milliseconds on a glass surface coated with the nanostructures; the droplets reached an equilibrium contact angle of 1°, as opposed to 34° for uncoated glass.

The angular nanostructure of the particles provides the coating with self-cleaning properties. Because nanoparticles extend from the surface at low angles everywhere, water vapor can infiltrate the spaces formed by nanoparticle overhangs, dislodging dust and grime from the surface. This is accomplished without UV activiation or any other catalytic process.

Existing antifogging coatings prevent the formation of water droplets on surfaces, but are effective only for a limited amount of time because they evaporate, can be accidently wiped-off, or lose their hydrophilicity over time. They also require regular reactivation with UV (ultraviolet) irradiation and many of them are toxic, preventing their use on dental and surgical devices.

Figure 1: Time-lapse images showing the spreading of a 0.5 ml water droplet after contacting uncoated glass (left) and glass coated with the superhydrophilic compound (right). (t, time; ms, millisecond)

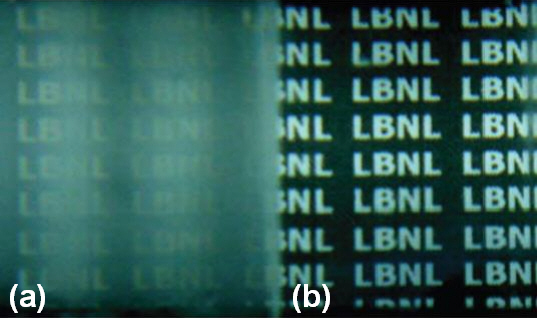

Figure 2: A glass slide was placed in a freezer (at -15°C) and then exposed to humid air at room temperature. The uncoated portion of the slide (a) has poor wettability/hydrophilicity, so moisture condenses on its surface in discrete droplets that scatter light and obscure the letters. The coated portion of the slide (b) allows water droplets to spread into a uniform film that does not scatter light, leaving the letters legible.

DEVELOPMENT STAGE: Functional prototype.

STATUS: Published patent application US2010/033927 available at www.wipo.int. Available for licensing or collaborative research.

FOR MORE INFORMATION:

Commercialization Analysis & Roadmap (June 1, 2012)

REFERENCE NUMBER: IB-2687