Yet just a few years ago a researcher at Lawrence Berkeley National Laboratory (LBNL) stood combustion theory on its head by developing an ultralow-emissions combustion technology for gas turbines that significantly reduces greenhouse emissions and pollution from electricity production.

LBNL’s low NOx combustion technology has already hit the market place in the product lines of industrial burners sold by Maxon Corporation of Muncie, Indiana. The climate-saving technology also is being developed in several collaborative projects for use in turbines that burn a variety of fuels.

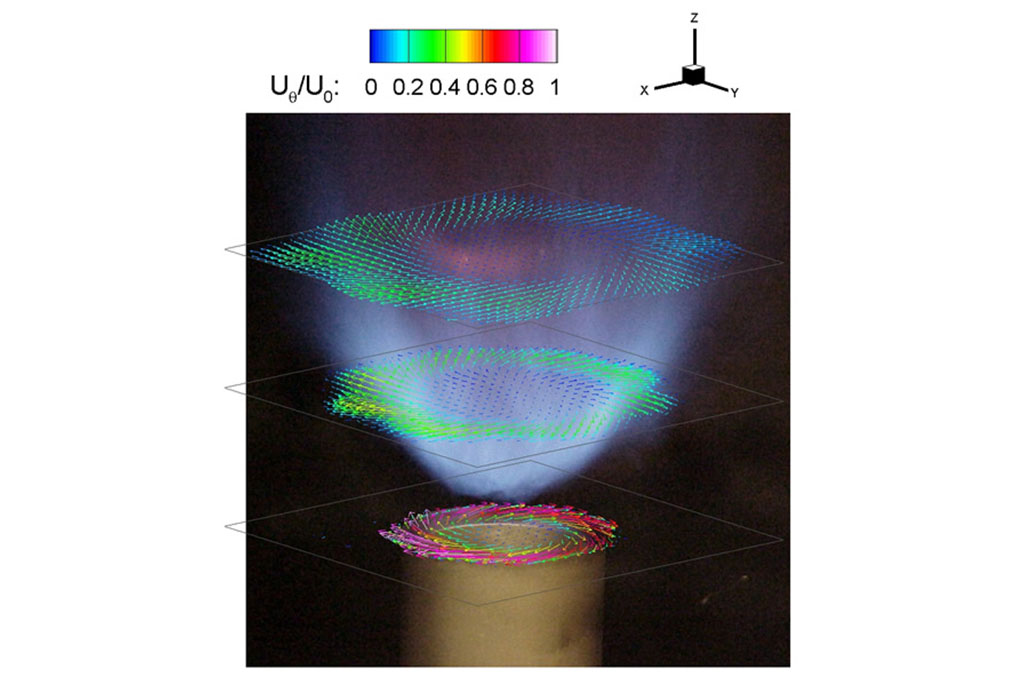

The novel technology, called the Low Swirl Injector (LSI), emits less than 2 parts per million (PPM) NOx – almost 10 times less than state-of-the-art burners. Unlike competing low NOx technologies which require high-cost sophisticated materials like precious metals and high temperature metal foams, the LSI produces low emissions with no cost premium, no need for substantial redesign of the basic gas turbine, and no need for expensive materials such as catalysts. It also has the potential to increase turbine system efficiency and performance.

The Department of Energy initially funded the development of LBNL’s LSI for use in industrial gas turbines for distributed electricity production. The purpose of this research was to develop a natural gas-burning turbine using the LSI’s ability to substantially reduce NOx emissions.

Inventor Robert Cheng and the LBNL Low Swirl Injector.

LSI inventor Robert Cheng, LBNL colleague David Littlejohn, and Kenneth Smith and Wazeem Nazeer from Solar Turbines Inc. of San Diego adapted the low-swirl injector technology to the company’s Taurus 70 gas turbine that produces about seven megawatts of electricity. The team’s effort garnered them an R&D 100 award in 2007 from R&D magazine as one of the top 100 new technologies of the year. LBNL and Solar Turbines are continuing their research collaboration in order to develop LSI for burning carbon-neutral renewable fuels available from landfills and other industrial processes such as petroleum refining and waste treatments.

A collaboration between LBNL and the National Energy Technology Laboratory (NETL) in Morgantown, WV, has taken the technology even further. In July 2008, the group successfully test-fired an LSI unit using pure hydrogen as its fuel. DOE’s Office of Fossil Energy is funding another project in which the LSI is being tested for its ability to burn syngas (a mixture of hydrogen and carbon monoxide) and hydrogen fuels in an advanced Integrated Gasification Combined Cycle (IGCC) plant called FutureGen. FutureGen is planned to be the world’s first zero-emissions coal power plant.

“The LSI principle defies conventional approaches,” says Cheng. “Combustion experts worldwide are just beginning to embrace this counter-intuitive idea. Principles from turbulent fluid mechanics, thermodynamics, and flame chemistry are all required to explain the science underlying this combustion phenomenon.”