APPLICATIONS OF TECHNOLOGY:

- Ultra-low emissions burners for residential and commercial gas appliances: furnaces and heaters, water heaters, gas cooktops, industrial heating

- Retrofits of legacy burners to meet emissions requirements

- Gas burners with customizable and scalable designs or visual features

BENEFITS:

- Stable fully premixed flames

- Highly efficient combustion in a single reaction zone

- Ultra-low NOx and CO emissions

- Modular and customizable for creative burner designs and retrofit applications

BACKGROUND:

- Lean premixed flames that mix fuel and air offer the potential to provide power output with very low pollutant emissions. However, premixed flames are highly unstable, especially when operating in a “natural draft” configuration, thus limiting the development and implementation.

TECHNOLOGY OVERVIEW:

Researchers at Berkeley Lab have developed a technology that is capable of stabilizing lean premixed flames of fuel and air as well as arresting the flame to prevent flashback. Two inventions are described below:

Low Velocity, Natural Draft Burner for Even Heating and Ultralow Pollutant Emissions (2015-052)

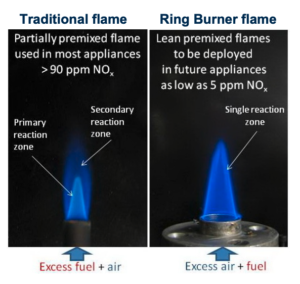

Currently there is no natural draft, ultra-low emission burner that operates at low velocities. As an example, cooktop ranges utilize a partially premixed natural draft flame stabilizer; but because the fuel and air are only partially premixed, a complete combustion requires secondary external air, which leads to heat losses to ambient air, and the NOx and CO emissions, harmful indoor air pollutants, emitted by the flame, are at levels unacceptable to the air quality goals of California.

Berkeley Lab combustion experts Robert Cheng and Peter Therkelsen invented a scalable burner that maximizes the heat transfer on flame surfaces for highly efficient combustion. The burner stabilizes premixed (air and fuel) flames at low velocities to reduce NOx emissions by 90% and CO emissions by more than 50%.

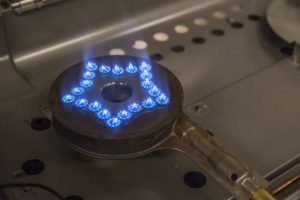

The Berkeley Lab Burner is a low velocity, natural draft burner that concentrates combustion energy in a single reaction zone of an air-rich flame (see Figure 1). Unlike other premixed burners that require air blowers, this natural draft technology offers both improved energy efficiency and low pollutant emissions to residential and commercial cooking operations, without the need for electricity or fans. The patent-pending burner technology can also be applied to other applications, including furnaces, ovens, heaters, water heaters, and industrial heating.

Flame Stabilizer (2019-156)

By stabilizing the lean premixed flames, this invention expands the use of lean (equivalence ratio from 0.59-0.70 for natural gas) premixed burners to support low emissions and improved efficiency.

The invention is a woven wire mesh/cloth that is placed directly under, and in contact with, the burner plate. Local velocity at the ports of the burner is increased to help ensure flow velocity of the unburned air and fuel mixture is faster than the speed at which the flame is burning. The components of the novel gas burner are modular and adaptable to any heat transfer applications, allowing customization for creative burner designs and large-scale burners.

This technology can also be used for retrofits of legacy burners to meet modern emissions standards and requirements.

DEVELOPMENT STAGE: prototype fabricated and demonstrated in a commercial propane camp stove and natural gas storage water heater

PRINCIPAL INVESTIGATORS:

- Vi Rapp

- Peter Therkelsen

- Robert Cheng

- Michael Tucker

STATUS: Patent pending.

OPPORTUNITIES: Available for licensing or collaborative research.