APPLICATIONS:

- Radiation heaters

- Industrial process heating, e.g., curing

- Food processing

BACKGROUND:

- Radiative heaters such as infrared (IR) heaters are readily available in the market; however, they suffer from two fundamental problems:

- The visible appearance of IR heaters greatly impacts the aesthetics of building interiors. As a result, these heaters have only been popular in outdoor and warehouse applications, where convective heating is impractical.

- IR heater coils for space heating are typically made of Nichrome, which operates at ~800 °C. The emission peak of these IR heaters is at ~3 μm, which coincides with strong liquid water absorption. Due to water absorption overhead, infrared heaters tend to overheat the exposed areas of the human body (face and head) and underheat the clothed areas (feet and legs), creating discomfort and skin dehydration.

- In manufacturing applications, the generally used UV curing technology suffers from a high system cost and is subject to the photochemical reaction, and the IR radiation curing technology is not very effective due to its very small penetration depth into the material. In addition, recent research has also shown that if the radiative energy is absorbed in the top few microns of the coating, film formation may occur before full removal of solvents, which affects the film quality. This makes long wavelength IR radiation (>3 um) undesirable in coating curing processes.

ABSTRACT:

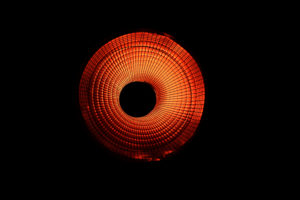

Researchers at Berkeley Lab led by Ravi Prasher have developed a near infrared (NIR) heater that is more efficient and increases human comfort in comparison to current appliances. The technology will enhance manufacturing productivity and energy efficiency in various heating applications.

This photonic device predominately radiates in the NIR range of electromagnetic wavelengths (0.7-3 μm). The major technical challenge was to design a multilayer stack that was thermally, chemically, and mechanically stable at high operating temperatures. Researchers overcame this problem by using materials that do not suffer from oxidation and are mechanically robust at high temperature. Therefore, the heater technology is capable of withstanding damages caused by the high temperatures associated with its industrial applications.

Other works have designed devices for selective infrared transmissivity over a range of wavelengths, while reflecting visible light. However, no other work has aimed specifically at spectral selectivity in the near infrared range between 0.7 and 3 μm for the applications mentioned above. In addition, the prior work regarding spectrally selective infrared filters and emitters employed materials that lack thermal, chemical and mechanical stability at high operating temperatures. The Berkeley Lab technology is the first spectrally selective near infrared transmitters/emitters that operate at high temperatures associated with the noted industrial applications.

BENEFITS:

- The multilayered photonic device uses cost-effective manufacturing processes that can be easily integrated with existing radiative heater manufacturing processes. Unlike the commercially available space heaters, the technology will provide more efficient and even heating with no glow and low water absorption from the skin. This enables even temperature distribution between bare skin and clothing.

- Additionally, the NIR device can be used in industrial heating processing with the advantage of rapid curing and uniform heating over the coating film and food processing with greater efficiency and reduced heating times in thicker organic materials.

DEVELOPMENT STAGE: Proven principle

STATUS: Patented. US Patent # 10873991. Available for licensing or collaborative research.

PRINCIPAL INVESTIGATORS:

- Ravi Shankar Prasher

- Hao Wang

- Justin Palmer Freedman

FOR MORE INFORMATION:

https://esdr.lbl.gov/publications/nano-photonic-filter-near-infrared

SEE THESE OTHER BERKELEY LAB TECHNOLOGIES IN THIS FIELD:

Combining Highly Sensitive Microarrays with Label-free Infrared Imaging 2014-015