E.O. Lawrence Berkeley National Laboratory

APPLICATIONS OF TECHNOLOGY:

- Use with a variety of filtered cathodic arc systems

- Deposition of dense, defect-free, continuous films

ADVANTAGES:

ADVANTAGES:

- Minimize plasma losses

- Maximize plasma throughput

- Maximize transport efficiency

- Greatly reduced likelihood of particle transmission

- Particles virtually eliminated from plasma

- Plasma distributed evenly over 4 inch or larger diameter

- Compatible with existing deposition equipment

ABSTRACT:

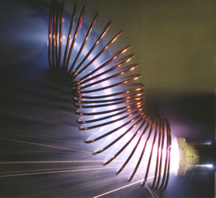

André Anders, Marcela Bilek, Robert MacGill, and Ian Brown have exploited conventional magnetic guiding to minimize plasma losses within a novel filter design, and thus maximize plasma throughput or transport efficiency. The curve describing the axis of the magnetic filter is “twisted”, and thus the filter is truly a three-dimensional device. The advantage of an out-of-plane filter is that the likelihood of particle transmission is greatly reduced and particles are virtually eliminated from the plasma. Filtering is more complete, without increasing the filter length and plasma losses in the filter. By means of this three-dimensional twist, as well as 2 other new, proprietary features, the new Berkeley Lab twist filter efficiently and completely filters out macroparticles while optimizing plasma throughput from the traditional 10-25% to over 50%. Throughput in the previous example is measured as the ratio of the number of plasma particles leaving the filter to the number entering it. Another way to quantify efficiency, the “system coefficient,” is a measure of the ratio of the ion current that can be extracted from the filtered plasma, to the plasma-producing arc current. Using Berkeley Lab’s new twist filter, the system coefficient for titanium plasma has been measured at levels as high as 7%, compared to the traditional 13%. These Berkeley Lab inventors have also utilized magnetic guiding of the plasma to spread the plasma beam and distribute it evenly over a 4 inch or larger diameter region. A compact system of coils and wires having a length of less than 20 cm allows the retention of a much greater proportion of the plasma than previously possible. The small length allows for the design of a filtered cathodic arc system that is compatible with existing deposition equipment. This filter and homogenizer can be used with a variety of filtered cathodic arc systems for the deposition of dense, continuous films that are defect-free.

See also Triggerless method of cathodic arc initiation, IB-1489, and Miniaturized Cathodic Arc Plasma Source, IB-1497.

STATUS: U.S. Patent #6,465,780. Available for licensing

REFERENCE NUMBER: IB-1484

SEE THESE OTHER BERKELEY LAB TECHNOLOGIES IN THIS FIELD: