APPLICATIONS OF TECHNOLOGY:

- Increasing production of a variety of products in specific plant tissue types. Examples include:

- Cereal crops: increased stem strength to reduce lodging and grain loss (e.g., in rice, wheat, barley, rye)

- Biofuels: reduced cell-wall recalcitrance in feedstocks (e.g., switchgrass, sugarcane, corn, poplar, eucalyptus)

- Low-water-use crops: preserving arable land for food

- Paper production: reduced pulping cost

- Forage: increased digestibility (e.g., of alfalfa, corn, ryegrass, fescue)

- Timber: hardier woods for construction (e.g., pine, poplar)

- Rubber: increases rubber production in rubber-producing plants

- A range of other applications

ADVANTAGES:

- Allows temporal and spatial control of gene expression and production of certain compounds in plants

- Applicable in a wide variety of plants: monocots; dicots; polyploids; sterile species

- Preserved normal plant growth

- Does not require genome sequencing or a particular genetic background in the target species.

- Examples of outcome-specific advantages include:

– Increased saccharification efficiency for biomass plants (up to twofold greater than that of wild types)

– Higher epidermal wax content for drought tolerance and efficient water use

– Denser biomass reduces biofuels transportation costs and may prevent lodging

ABSTRACT:

Dominique Loqué, Henrik V. Scheller, and colleagues at the Joint BioEnergy Institute (JBEI) have developed a technology that can be used to fine-tune desirable biomass traits in plants. A key feature of the invention is the design of an artificial positive feedback loop whereby a transcription factor induces increased transcription of itself.

Gene promoters are selected according to the desired outcome, for example, to improve saccharification efficiency or to raise the level of desirable hexose sugars in relation to hard-to-ferment pentoses. Some promoters can boost secondary cell wall deposition of cellulose; others can decrease deposition of lignin or hemicellulose (xylan). With similar promoter engineering, increased wax production can be directed to the epidermal layers of a plant, improving drought tolerance and efficient water use while preserving energy for increased production of biomass.

This versatile technology can be used to improve crops used for biofuels and paper production; provide livestock with more digestible forage; extend the range of crops to marginal land; or produce stronger timber for construction, among other applications. Unlike other genetic engineering methods, when applied to increasing secondary cell wall deposition, the JBEI technologies alter biosynthesis in plant fibers but not in vascular tissue or leaves. Thus they do not adversely affect growth, fertility, or the fruit- or grain-bearing capacity of the plants.

Because this new method involves dominant traits and uses genetic promoters that are part of conserved pathways, it will be applicable across many species, including polyploids and sterile plants. Moreover, its application does not require sequencing of the entire genome of the target plant or the presence of a particular variety or cultivar.

To date, the technology has been applied to four applications, described below:

EIB-2930 Controlling Lignin Deposition

To fine-tune lignin deposition, the scientists started with a mutant of Arabidopsis that under-produces lignin in all tissues. The JBEI scientists then selectively restored lignin biosynthesis to vascular tissue but not fiber cells by expressing a wild-type allele under the regulation of a promoter that is expressed only in vascular tissue. The engineered plants were morphologically and developmentally identical to the wild type, but they had a total lignin level that was approximately 33% less. When tested with several different pretreatment methods, biomass from the engineered plants had a saccharification efficiency 1.5-2.3 times greater than that of wild types.

Lignin is the primary source of cell wall recalcitrance and the main factor limiting efficient conversion of biomass to biofuel, digestibility of forage, and pulping efficiency. Improved feedstock would produce less lignin and have traits that facilitate cellulose extraction and/or its enzymatic hydrolysis.

EIB-3003 Controlling Xylan Deposition

Using a method similar to that described above, the scientists started with a mutant with a defective allele for a key gene in xylan biosynthesis. They then selectively restored expression of a normal allele to vascular tissue only. The resulting plants have a reduced amount of hemicellulose relative to cellulose. Thus, compared to wild types, these plants can be pretreated more easily for biofuel production, yield more glucose per unit of biomass, and produce fewer low-value byproducts such as pentose from biofuels production or black liquor from pulping.

Like lignin, xylan contributes to the recalcitrance of cell walls. In addition, xylan is composed of pentoses, which are sugars that are not efficiently fermented into bioproducts.

EIB-2996 Increasing Wood Density and Drought Tolerance

In this application, promoters are used in a positive feedback loop to increase traits such as wood density or drought tolerance. To boost wood density, JBEI scientists upregulated a transcription factor that induces the expression of genes involved in secondary cell wall synthesis in native tissues. This upregulation occurs only in fiber cells and in a manner that does not interfere with growth, cell expansion, or nutrient transport.

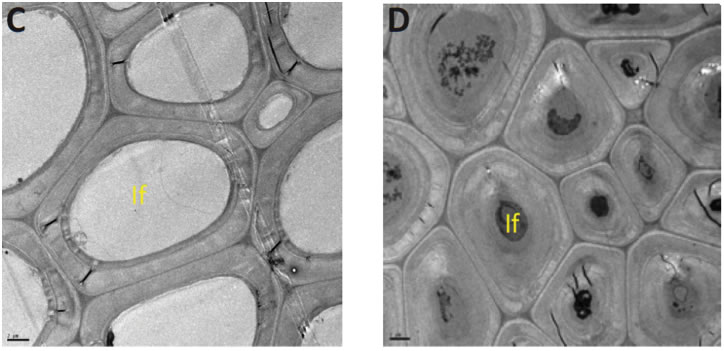

Examples of these cells are shown in Figure 1. When this technology was combined with the fine-tuning of lignin deposition (EIB-2930), stem density was increased by almost 20% and the saccharification efficiency was two- to three-times greater than that of wild types. While boosting yields, the technology can also decrease the cost of transporting biomass from the field to the biorefinery. In addition, it can increase the stem strength of cereal crops or boost the strength of timber used for construction.

EIB-3085 Increasing Wax and /or Cutin Content in Targeted Tissues

The positive feedback loop can also be applied in plant epidermal cells to maintain overexpression of transcription factors involved in wax/cutin biosynthesis. Increased wax deposition leads to greater drought tolerance and more efficient water use. The combined promoter/transcription factor technologies can therefore be used to engineer plants that not only produce biofuels more efficiently, but do not compete for arable lands more suitable for growing food crops.

EIB-2014-028 Increasing Production of Rubber in Rubber-producing Plants

Figure: The left electron micrograph shows cell walls in fiber cells from wild type plants. The right panel shows fiber cells in genetically engineered plants that overexpress genes involved in secondary cell wall synthesis.

DEVELOPMENT STAGE: Proven principle.

STATUS: Published PCT Patent Application WO2012/103555 available at wipo.int. Available for licensing or collaborative research.

Published Patent Application US2016/025695 (Publication US2018/0127767). Available for licensing or collaborative research.

Published PCT Patent Application US2017/048934 (Publication WO/2018/097871). Available for licensing or collaborative research.

FOR MORE INFORMATION:

RELATED TECHNOLOGIES:

Lignification Stoppers, EIB-2929

Energy Crops Engineered for Increased Sugar Extraction through Inhibition of SNL6 Expression, EIO-2763

Feedstocks with Reduced Acetylation for Higher Product Yields and Improved Properties, EIB-2658

The Joint BioEnergy Institute (JBEI, www.jbei.org) is a scientific partnership led by the Lawrence Berkeley National Laboratory and including the Sandia National Laboratories, the University of California campuses of Berkeley and Davis, the Carnegie Institution for Science and the Lawrence Livermore National Laboratory. JBEI’s primary scientific mission is to advance the development of the next generation of biofuels.