APPLICATIONS OF TECHNOLOGY:

- Agriculture

- Biosciences research

ADVANTAGES:

- Improved sterile, automated processing of EcoFABs

- Scalability of EcoFABs due to injection molding fabrication

- Compatible with typical automated platforms

- Smaller footprint and lower price than existing automated systems

- Adaptive system

ABSTRACT:

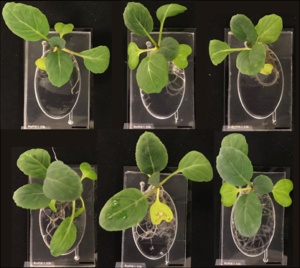

Berkeley Lab’s EcoFABs are precisely controlled compartments in which researchers conduct controlled, replicable laboratory experiments to study microbiomes using small plant and microbe growth chambers. Researchers led by Berkeley Lab’s Trent Northen have developed a new iteration of the EcoFAB device enabling improved operation, to scale. To date, there have been over 2000 EcoFAB units already ordered.

Design changes in the EcoFAB 2.0 include

- Standardization of the EcoFAB base to be compatible with existing biological sample analysis platforms

- Features enabling production via injection molding

- Sealed sampling ports outside the growth chamber

- Sloped growth chamber incorporated into EcoFAB’s flat base

- Ridges enabling automated handling

- Exterior sampling ports designed to avoid impact from roots

The design changes make EcoFAB 2.0 compatible with automated systems found in most molecular biology laboratories and enable a more straightforward approach to maintaining asceptic technique. The new iteration will also enable larger quantities of EcoFAB 2.0 device through injection molding fabrication.

STATUS: Patent pending. Available for licensing or collaborative research.

SEE THESE OTHER BERKELEY LAB TECHNOLOGIES IN THIS FIELD:

EcoFAB Plant Growth Chambers for Microbiome Research 2017-048